We have a formalised system of four stages to carefully scrutinize all our products to complement the needs of our clients.

Stage 1 - Farming

Stage 2 - Production Process

Stage 3 - Packaging / Private Labels

Stage 4 - Supply to World

Peanut Processing Plant Steps

Step 1.Raw Material Storage

Products Stored In Dry And Ventilated In-House Warehouse. Pest Control Has Been Carried Out As Per The Required Interval. The Warehouse Is Having Natural Ventilation System For Removal Of Heat And Excess Moisture From The Product As They Cure And Reaches Moisture Equilibrium.

Step 2.Pre-Cleaning

Dust, Stones, Mud, Sand, Leaves, Shrivelled & Undeveloped Pods, Small Inshells And Any Other Foreign Materials Are Removed From Related Product In Pre Cleaning Section. This Is Used To Cleaning Any Kind Of Agriculture Whole Oil Seeds & Spices Products, Where Goods Are Sold As Per Their Count Per Oz.

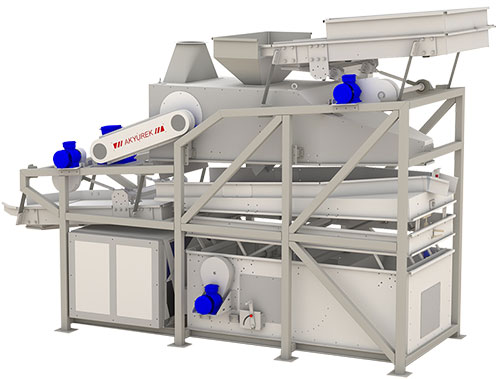

Step 3.De-Stoner and Gravity Separator

Gravity Based De-Stoner Is Used To Separate Related Product From Stone, Mud Metal, Glass And Other Heavy Impurities Based On Different Gravity Of Materials.

I.E. Impurities Which Are Heavier Than Product As Well As Light Air Borne Impurity.

Gravity Separator

Relevant Products Are Cleaned By Gravity Separator Which Separates Impurities, Shrivelled Seeds, Light Seeds, Pods, And Damaged Seeds Etc. This Operation Ensures That Only Good Quality Material Go Further In The Process.

This Unit Is Used To Separate Light Air Borne Particles And Hollow Or Immature Seeds As Well As Grading Of Material By Sizes.

Step 4.Sorting Operation

In This Process Relevant Products Are Graded By Their Colour To Ensure A Uniform Appearance For Added Value. This Operation Results In Reduction Of Microbiological & Aflatoxin Levels Through The Efficient Removal Of Discoloured, Diseased And Damaged Seeds.

Step 5.Uniform Grading

In This Operation, Seeds Are Graded As Per The Count / Ounce) Specified By The Buyer In Three Stage Uniform Grading Process.

Step 6. Metal Separation

Online Metal Separator Detects And Separates Any Kind Of Metallic Foreign Material Before Packing Of The Final Product.

Pre Shipment Lab. Analysis

We Have Tied Up With Majority Reputed Laboratories / Inspection Vendors For Testing Of Various Parameters As Per Buyer Requirements Like Pesticides, Salmonella, E Coli, Aflatoxin, FFA, Oil, Purity, Impurity, Admixture, Etc. Few Of Them We Have Our Own In-House Lab. Facilities / Equipments For Testing Parameters Like Aflatoxin,Moisture, Purity, Impurity & Admixture.

Step 7.Packing

We Offer From 10 Kg. To 50 Kg. Packaging In Food Grade PP / Paper /Jute Bags As Per Specific Importer Labelling / Marking. All Require Packing We Fulfill By Trained Workers Directly Stuff Goods Into The Container At Our Factory Premises Under Expert Supervision And In A Scientific Manner. Thus The Chances For Any Sort Of Pilferage Or Weight Shortage Are Minimized.

Quality is a top priority at Parth Agro World, hence lab tests and certifications for our cargos are obtained on a regular basis. Apart from that we also provide weight and quality reports to our clients on the basis of their requirements.

Parth Agro World has been able to retain on the top spot in the market for over a decade due to our devoted team who work tirelessly through all stages to enhance customer satisfaction and engage with happy clients.